MX Series

Mist Dust Collector

- Product Usage

- Machining Center, Automatic lathe, Milling processing, Hobbing machines, Tapping machines, Electro-discharge machines, Sspray painting, Selection of materials, etc.

- Certification Status

-

Product Features

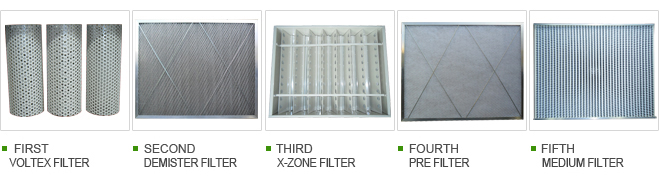

| - X-ZONE FILTER SYSTEM | |||||||||

| - It is mounted with a permanent filter that doesn't need replacement due to its perfect mechanical dust collection function so that there is no inconvenience of frequent replacement.-no filter replacement | |||||||||

| - Due to the large capacity, the system can remove mist collected from distributed machines | |||||||||

| - Accredited by Korea Occupational Safety and Health Agency | |||||||||

| - The hepa filter and activated carbon filter are optionally mounted if needed. | |||||||||

- The patent registered filter mounted (No. 10-0899733)

--

* Mist Deletion Principle of the X-Zone Filter System Stage 1: The minute oil floating in the air is attached to the 1st collision panel. * System Organization

| |||||||||

Installation Cases

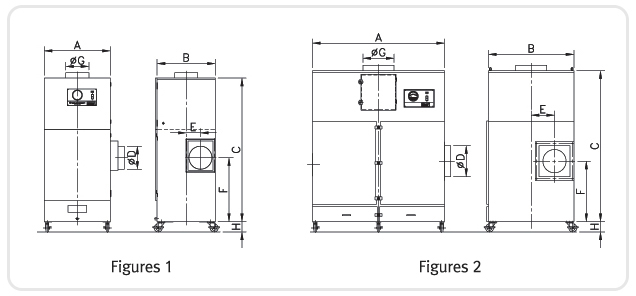

Standard Dimension

Specification

| Type | MXV-100 | MXV-200 | MXV-300 | MXV-500 | MXV-750 | MXV-1000 | |||||||||||||

| POWER SOURCE | 220V 1P, 220/380V 3P 60Hz | 220V / 380V 3P 60Hz, 440V(Option), 50Hz(Option) | |||||||||||||||||

|

BLOWER

(60HZ) |

Airflow(m³/min) | 0 | 12 | 15 | 0 | 25 | 35 | 0 | 40 | 68 | 0 | 60 | 85 | 0 | 80 | 140 | 0 | 100 | 150 |

| Constant Pressure(mmAq) | 290 | 200 | 160 | 300 | 230 | 125 | 260 | 230 | 200 | 330 | 230 | 200 | 310 | 250 | 120 | 330 | 250 | 150 | |

|

BLOWER

(50HZ) |

Airflow(m³/min) | 0 | 10 | 12 | 0 | 20 | 30 | 0 | 35 | 65 | 0 | 50 | 62 | 0 | 70 | 120 | 0 | 100 | 120 |

| Constant Pressure(mmAq) | 190 | 150 | 110 | 210 | 200 | 50 | 180 | 200 | 120 | 230 | 200 | 190 | 240 | 200 | 90 | 240 | 200 | 190 | |

| MOTOR(kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 3.7 X 2 SET | |||||||||||||

| SIZE | A(mm) | 670 | 670 | 850 | 850 | 1,344 | 1,650 | ||||||||||||

| B(mm) | 600 | 600 | 750 | 750 | 900 | 950 | |||||||||||||

| C(mm) | 1,200 | 1,350 | 1,600 | 1,750 | 1,900 | 1,900 | |||||||||||||

| ØD(mm) | 150 | 200 | 250 | 250 | 300 | 350 | |||||||||||||

| E(mm) | 240 | 215 | 260 | 260 | 275 | 275 | |||||||||||||

| F(mm) | 345 | 295 | 660 | 660 | 640 | 635 | |||||||||||||

| ØG(mm) | 150 | 200 | 300 | 300 | 350 | 400 | |||||||||||||

| H(mm) | 128 | 128 | 128 | 128 | 160 | 160 | |||||||||||||

| Approximate Weight (㎏) | 120 | 165 | 280 | 305 | 680 | 710 | |||||||||||||

| Figures | Figures 1 | Figures 2 | |||||||||||||||||

* The power code is a 4-core cap diameter cable and 3m is added.

* The specification can change without a prior notice to improve the performance.

ETC

USA / English

USA / English Korea / 한국어

Korea / 한국어 China / 中文

China / 中文 Japan / 日本語

Japan / 日本語